Stainless Steel Boiler Tubes, SS Boiler Tubes/Condenser Tubes, Certificated CE, RoHS

- Heat Exchanger Tubes & Pipes

- Wuxi Dingjisheng Equipment Manufacturing Co., Ltd.

PED Stainless Steel Boiler Tubes, Cooling Tower Tubes/Condenser Tubes, Certificated CE, RoHS

Details

|

| Wuxi Ding Jisheng Heat Exchanger Tube Catalog |

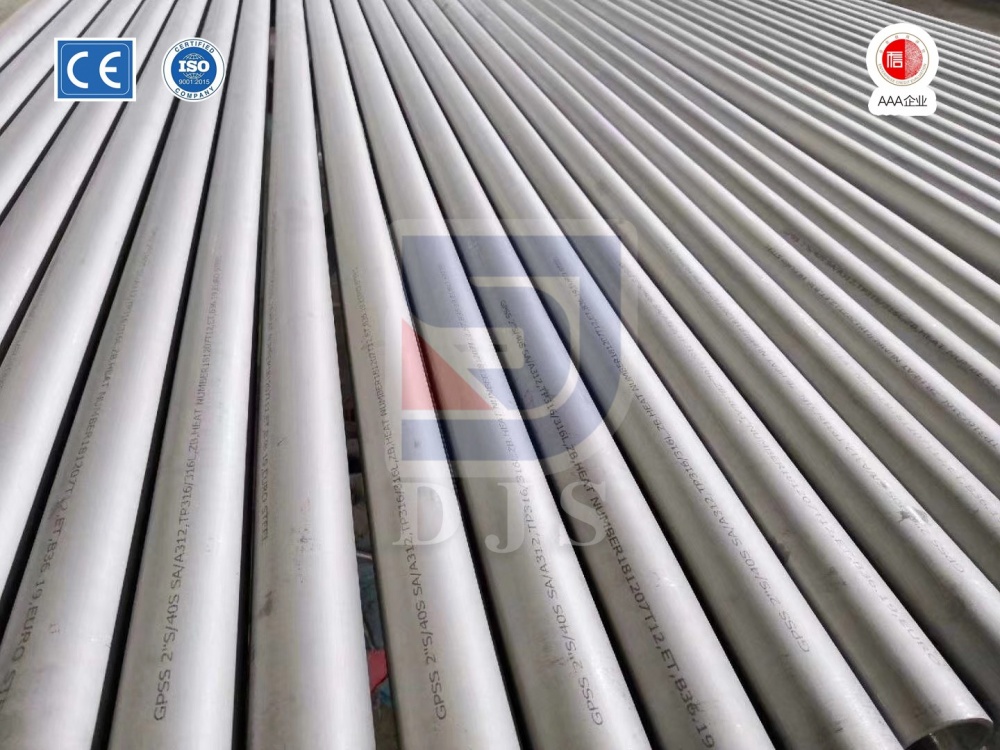

PED PASSED Stainless Steel Boiler Tubes, Ss Boiler Tubes/Ss Condenser Tubes, Certificated CE, RoHS

Stainless Steel Heat Exchanger Tube

Stainless steel heat exchanger tube is generally used for boiler, heat exchanger, condenser, standards are A249 welded tube and A213 seamless tube, 304 / 304L, 316 / 316L, 310S, 2205, S31803 stainless steel grades, annealing pickling or bright annealing condition.Stainless steel tube has high temperate resistance and corrosion resistance, used for heat transfer processes and mostly applied in heating, cooling, condensation and evaporation of liquids, gases and steam. Heat exchanger tubes are always cold finished condition and resistant to corrosion.Basic specification.

| Welded |

ASTM A249 ASTM A269 ASTM A789 |

| Seamless |

ASTM A213 ASTM A269 ASTM A789 |

| Grades | TP304 / 304L, TP316 / TP316L, TP321 / TP321H, 2205 / S31803, TP310S. |

| Surface |

Annealing Pickling Bright Annealing |

| Outside Diameter | 6.53 Mm - 127 Mm |

| Thickness | 0.5 Mm - 5 Mm |

| Tolerance | +/-0.05 Mm |

| Application | Heat Exchanger, Boiler, Condenser, Cooling, Heating |

Welded Stainless Steel Tube For Heat Exchanger

Welded stainless steel tube is used in heat exchanger system, annealing pickling or bright annealing finishes are aailable, tube welding bead should removed and grinding inside and outside to ensure smooth surface, it is easy to clean inside heat exchanger, Dingjisheng Stainless is a welded stainless steel tube suppliers which can offer U bend tube and coil tube for various types of heat exchanger.| ASTM | ASME |

| A-789 | SA-789 |

| B-163 | SB-163 |

| A-249, A-269 | SA-249 |

Seamless Stainless Steel Tube For Heat Exchanger

Seamless stainless steel heat exchanger tube, covering kinds of stainless steel grades to meet various requirement, minimum wall thickness or average wall thickness as agreement, cold drawn and cold rolled finishing, control tolerance of outside diameter, wall thickness and length, testing and inspection as standard Dingjisheng to manufacture high quality heat exchanger tubes.| ASTM | ASME | EN |

| A-789 | SA-789 | 10216-5 |

| B-163 B-407 | SB-163 SB-407 | 10216-5 |

| B-668 | SB-668 | 10216-5 |

| A-269 | SB-677 | 10216-5 |

| A-213 A-269 | SA-213 | 10216-5 |

Heat Exchanger Tube Materials

Austenitic Stainless Steels

| UNS | ASTM | EN Steel No. | W.-Nr |

| S30403/S30400 | 304L/304 | 1.4306/1.4301 | 1.4306/1.4301 |

| S31603/S31600 | 316L/316 | 1.4435/1.4436 | 1.4435/1.4436 |

| S31635 | 316Ti | 1.4571 | 1.4571 |

| S32100/S32109 | 321/321H | 1.4541/1.4940 | 1.4541/1.4878 |

Duplex Stainless Steels

| UNS | ASTM | EN No. | W.-Nr |

| S31500 | - | 1.4424 | 1.4417 |

| S31803/S32205 | - | 1.4462 | - |

| S32304 | - | 1.4362 | 1.4362 |

| S32707 | - | - | - |

| S32750 | - | 1.4410 | - |

High-Alloy Austenitic Stainless Steels And Nickel Alloys

| UNS | ASTM | EN Steel No. | W.-Nr |

| N06600 | Alloy 600 | - | 2.4816 |

| N06690 | Alloy 690 | 2.4642 | 2.4642 |

| N06625 | Alloy 625 | - | - |

| N08825 | Alloy 825 | - | 2.4858 |

| N08800 | - | 1.4558 | 1.4558 |

| N08028 | - | 1.4563 | 1.4563 |

| N08904 | - | 1.4539 | 1.4539 |

| S31254 | 254SMO | 1.4547 | (1.4529)** |

Heat Exchanger Applications

Heat exchanger is a device used to transfer heat between a solid object and a fluid, or between two or more fluids in different temperature, transfer heating from higher temperature fluid to lower temperature object to make fluid temperature to specified requirement, for stainless steel grades, there are shell and tube heat exchanger, plate heat exchangers, plate and shell heat exchanger and other heat exchanger, tube heat exchanger consists of a number of tubes inside bundle and sheet, widely used in many industries.- space heating

- refrigeration

- air conditioning

- power stations

- chemical plants

- petrochemical plants

- petroleum refineries

- natural-gas processing

- wine and beer making

Custom Stainless Steel Heat Exchanger Tube Size

| OD/WT (Mm) | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | 1.2 | 1.5 | 1.65 | 2.0 | 2.11 | 2.5 | 3.0 |

| 12.7 | • | • | • | • | • | • | • | ||||||

| 14 | • | • | • | • | • | • | • | • | • | ||||

| 15 | • | • | • | • | • | • | • | • | • | ||||

| 16 | • | • | • | • | • | • | • | • | • | ||||

| 19.1 | • | • | • | • | • | • | • | • | • | • | • | ||

| 20 | • | • | • | • | • | • | • | • | • | • | • | ||

| 22 | • | • | • | • | • | • | • | • | • | • | • | ||

| 23 | • | • | • | • | • | • | • | • | • | • | • | ||

| 25.4 | • | • | • | • | • | • | • | • | • | • | • | • | |

| 28 | • | • | • | • | • | • | • | • | • | • | • | • | |

| 30 | • | • | • | • | • | • | • | • | • | • | • | • | |

| 31.8 | • | • | • | • | • | • | • | • | • | • | • | • | |

| 34 | • | • | • | • | • | • | • | • | • | • | • | • | |

| 35 | • | • | • | • | • | • | • | • | • | • | • | ||

| 38.1 | • | • | • | • | • | • | • | • | • | • | • | ||

| 40 | • | • | • | • | • | • | • | • | • | • | |||

| 42.2 | • | • | • | • | • | • | • | • | • | • | |||

| 44.5 | • | • | • | • | • | • | • | • | • | • | |||

| 50.8 | • | • | • | • | • | • | • | • | • | ||||

| 60.3 | • | • | • | • | • | • | • | • | |||||

| 63.5 | • | • | • | • | • | • | • | • | |||||

| 76.2 | • | • | • | • | • | • | • | ||||||

| 88.9 | • | • | • | • | • | • | • | ||||||

| 101.6 | • | • | • | • | • | • | • |

Whatsapp

Whatsapp